Induced Draft Fan Design Calculation

D sizing calculations of id fan.

Induced draft fan design calculation. To describe the general operation of callide c power station with special attention to boiler section pertaining to induced draft id fan operations. Verification of design of draught fans a induced draft fan given. Induced draft id fan lubrication system and recommend a cost effective and reliable design for a future modification project. Induced draft fan or id fan is required to evacuate the exhaust gases from boiler to atmosphere through duct collectors and chimney.

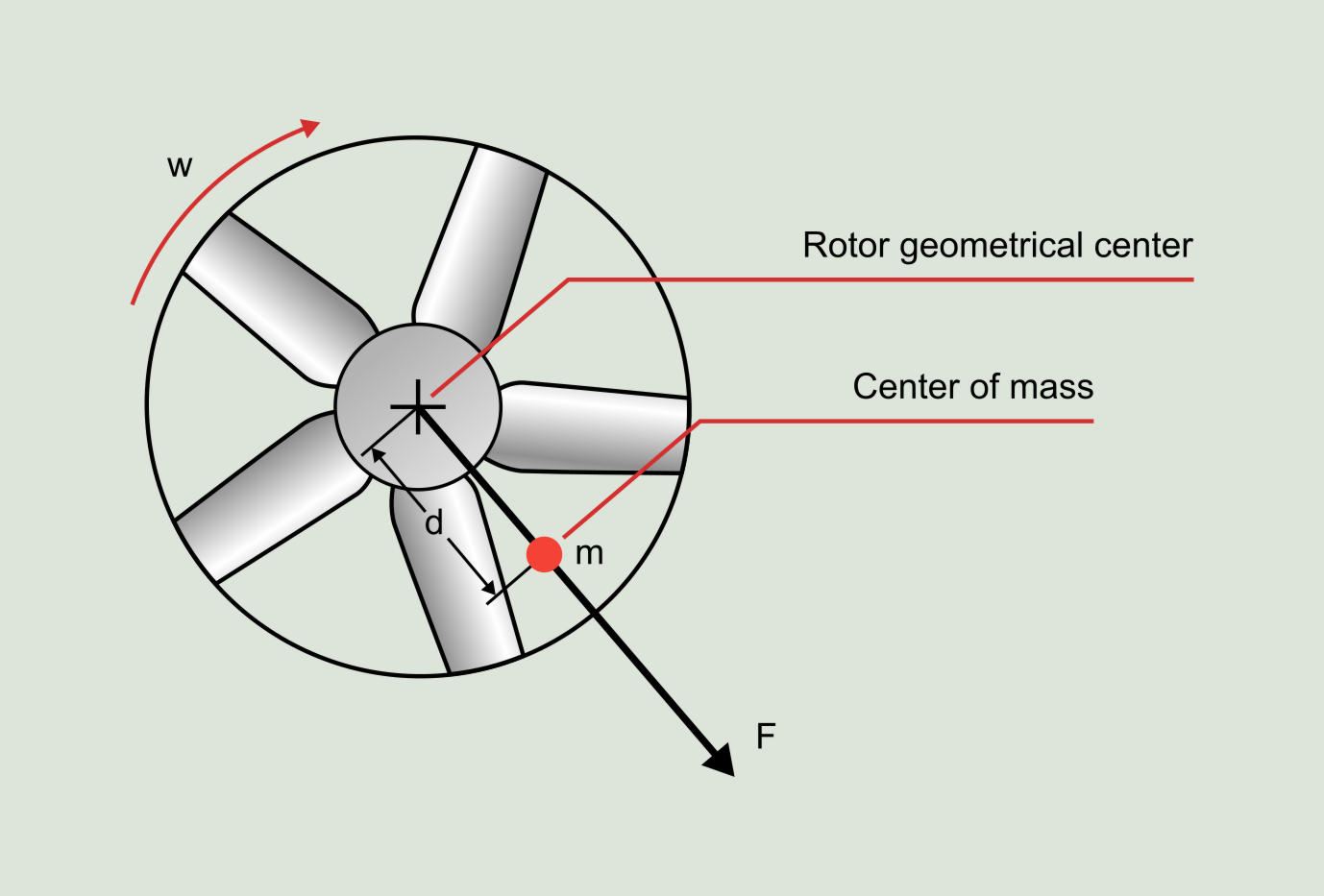

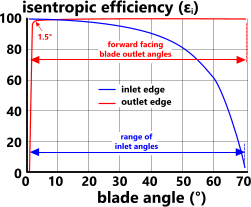

Id fan motor power calculator. The id fan exhausts flue gases from the furnace and induces combustion air into the furnace by having the furnace operated under negative pressure. The induced draft id fans and forced draft fd fans provide control for draft and forced air zoning of fuel burned furnaces of steam generation plant of a thermal power plant. Impeller axial centrifugala sirocco etc.

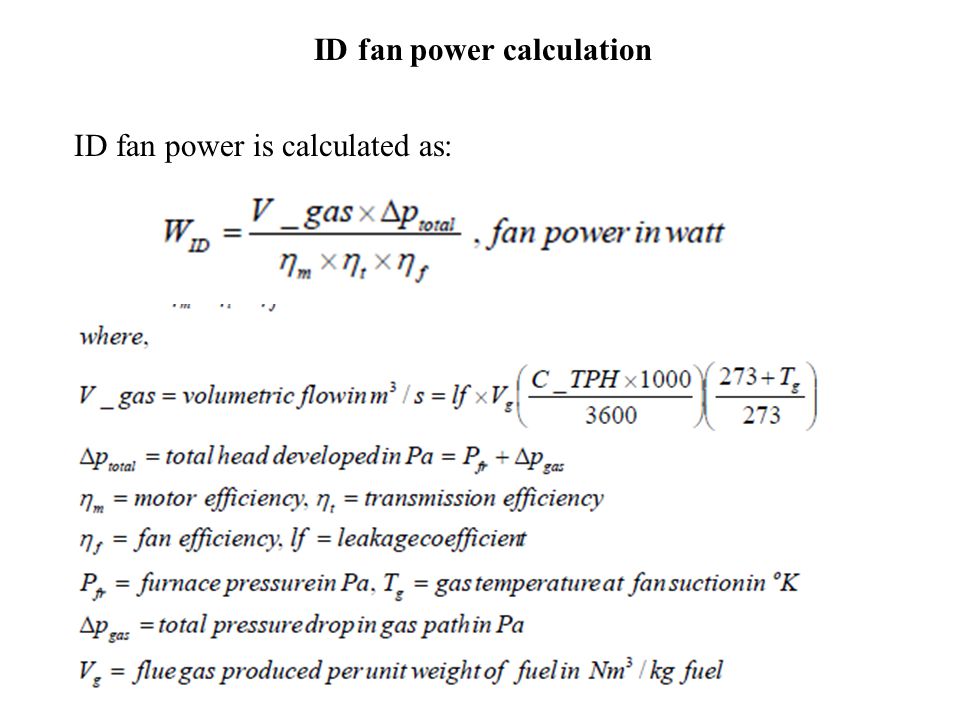

Motor power required for its working depends upon the following factors id fan capacity quantity of flue gases drawn from the system measured in m 3 hr. Ft min temperature at air pre heater outlet 520f allow 20 margin on fan capacity 202 800 cu ft min previous fan water gage design 9 36 previous fan hp mcr previous rpm 370 920 640 920. Usually id should take care of draft loss across the boiler from furnace to air heater and then draft loss across duct collectors like esp wet scrubber or mechanical type cyclone dust collectors etc. Induced draft id fan is used to draw the flue gases from the system generated from the combustion of fuel.

All of which have individual benefits volume pressure speed power efficiency etc but all of them will shift gases at the same rate based upon the input power.