Iso Class 8 Clean Room Air Changes

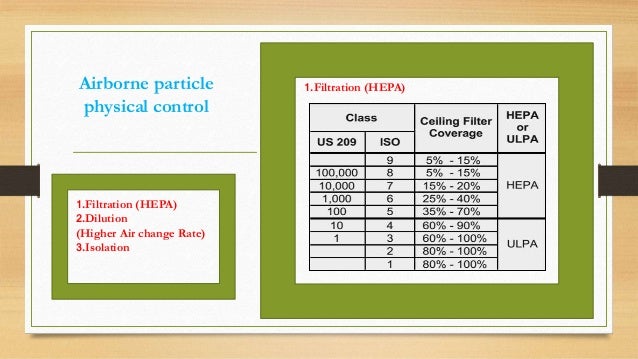

The use of hepa filters and ulpa.

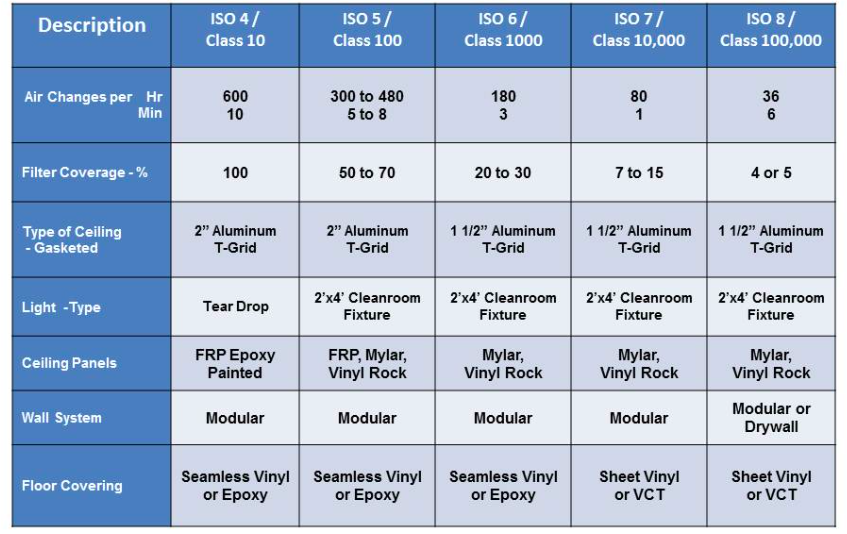

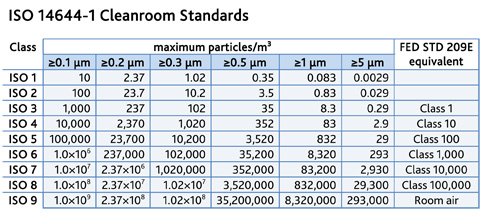

Iso class 8 clean room air changes. Iso class 8 5 60 air changes per hour with a ceiling coverage of 5 15. The requirement of number of air changes per hour for any clean room depends on the class of the room number of personnel working in the area and frequency of access the room. This table details the recommended air changes per hour for iso 14644 1 2015 cleanrooms and their associated gmp grade and federal standard. Food industries ultimately depend on secure cleanroom environments for food safety.

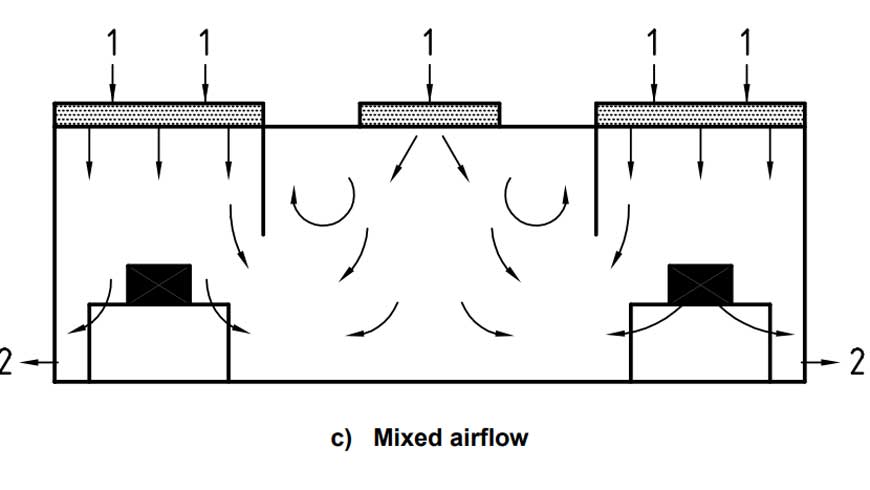

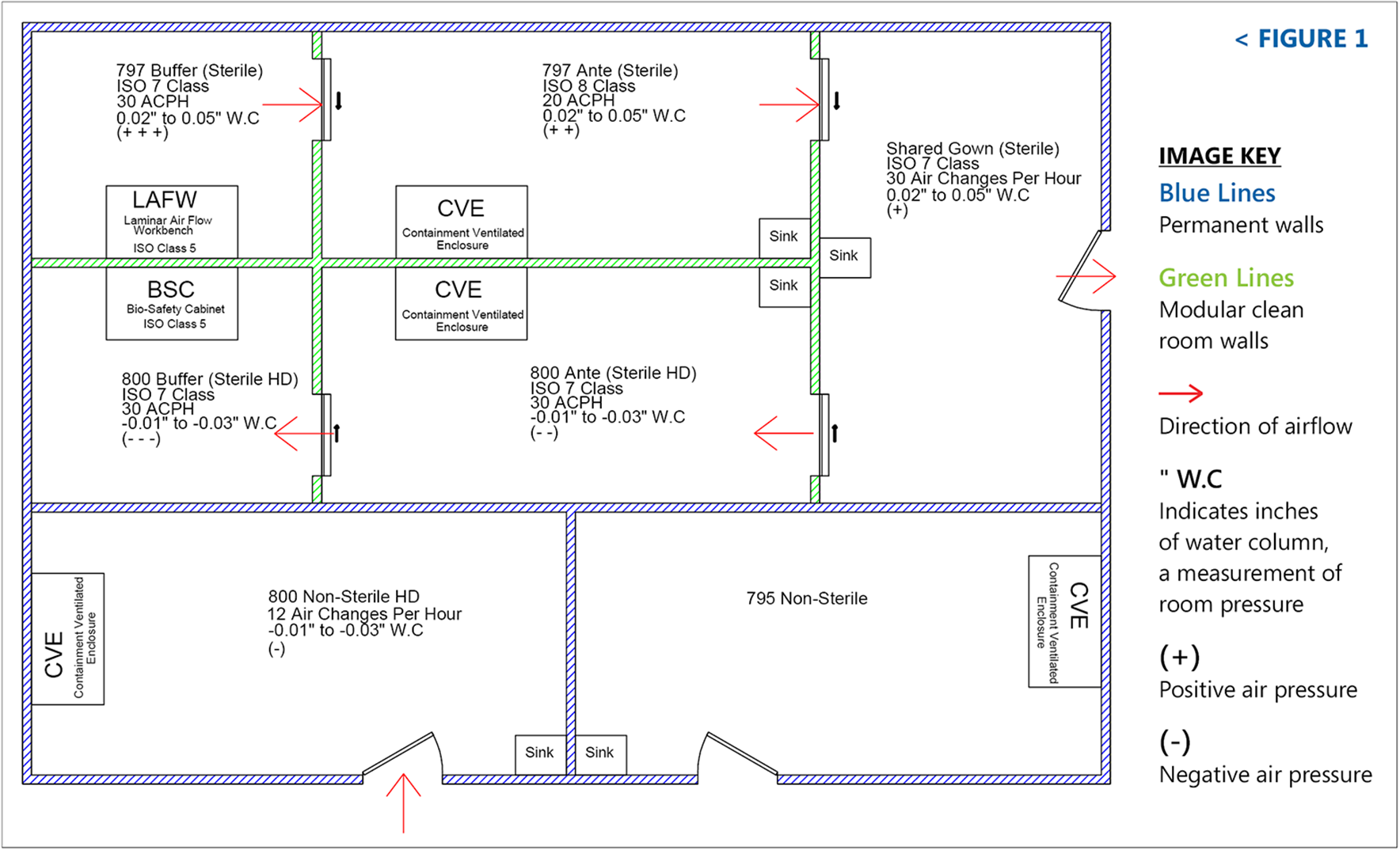

Iso 8 class 100 000 0 005 0 041 1 8 5 48. D recommended air changes per hour ach. Iso 7 class 10 000 0 051 0 076 10 15 60 90. It s suggested that in cleanrooms with unidirectional airflow patterns iso class 1 5 air exchange rates can be calculated by average air velocity.

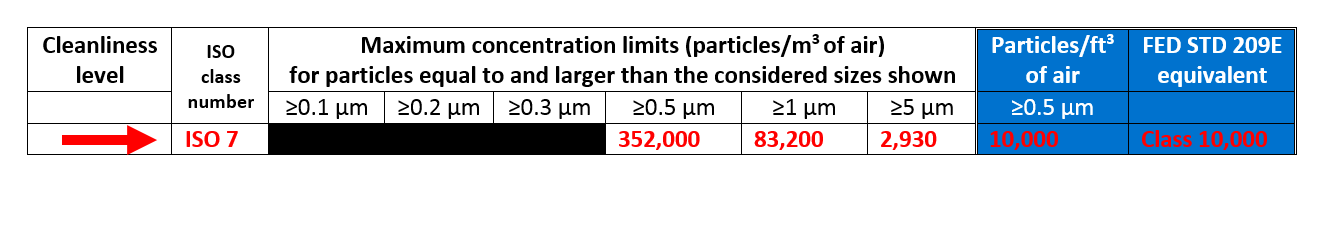

For cleanrooms and clean zones shown in iso 14644 1 2015. Grade c is equivalent to class 10 000 or iso 7. Maximum allowable concentrations by cleanroom class. Iso class 9 g.

Iso 6 class 1 000 0 127 0 203 25 40 150 240. The rule of thumb is that you should not skip over more than one class when you move towards a cleaner room for example from iso 7 to iso 6 not from iso 8 to iso 6 as illustrated below. N is the iso class number which must be a multiple of 0 1 and be 9 or less d is the particle size in micrometers maximum concentration limits particles m3 of air class 0 1 µm 0 2 µm 0 3 µm 0 5 µm 1 µm 5 µm iso 1 iso 2 iso 3 iso 4 iso 5 iso 6 iso 7 iso 8 iso 9 10 100 1000 10000 100000 1000000 2 24 237 2370 23700 237000. Cleanroom grades a d should employ a broad range of techniques and cleaning practices to meet these guidelines.

Iso 5 class. Class 100 000 associated eu gmp grade. Cleanroom industry requirements fall under iso 14644 5 2004 an iso category that lists the basic requirements for cleanroom operations. Federal standard 209e equivalent.

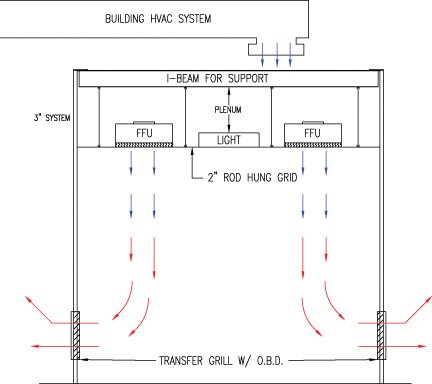

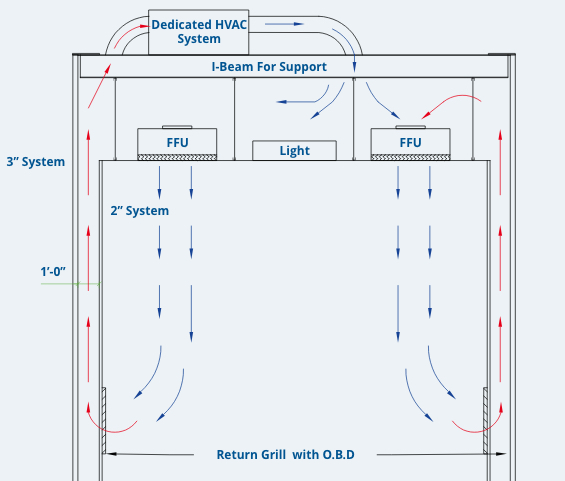

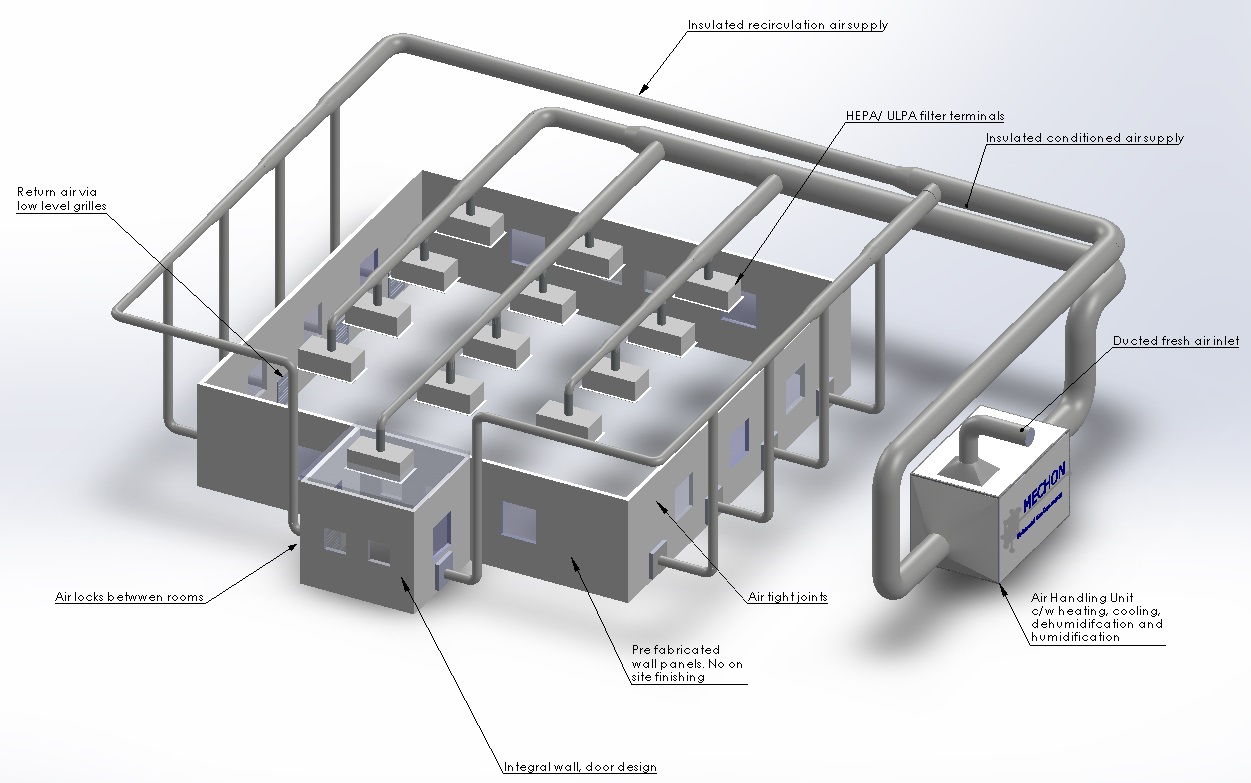

Considerations for iso class 8 cleanrooms. Calculating cleanroom air change rates for iso 1 5 in cleanrooms with unidirectional airflow air exchange rate is calculated by air velocity sampling. This includes an air circulation system that works effectively. 5 48 typically measured micron sizes.

More air changes per hour are required for the better clean room class than the lower one. Medical companies work with iso class 7 and iso class 8 to avoid surface contamination. Cleanroom limits for airborne particulate contamination. Information on iso 14644 1 2015 class 8 cleanroom classification.

Class iso 146144 1 federal standard 209e average airflow velocity m s ft min air changes per hour ceiling coverage. Grade d is equivalent to class 100 000 or iso 8. In reality however you can reach a cleaner class with fewer airlocks than described below with the appropriate air changes per hour.