Kevlar Vs Carbon Fiber Weight

The actual figures presented here are for comparison only.

Kevlar vs carbon fiber weight. Builders choosing carbon fiber are getting a material that offers exceptional strength and lower weight. All the answers are pretty good. However as a chemist and somebody who worked on polymer science and materials i feel there are a few missing points which could help explain some of the characteristic properties of carbon and kevlar fibers. Kevlar fiber has a tensile strength comparable with that of carbon fiber a modulus between those of glass and carbon fibers and lower density than both.

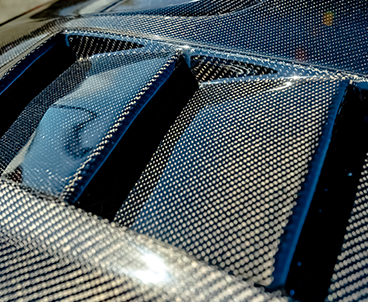

This stiffness provides faster acceleration and a very maneuverable hull. Kevlar usually positioned internally in all areas of stress in carbon hulls carbon kevlar hybrids. High rigidity young s modulus stiffness. Kevlar carbon fiber hybrid a mixture of the best in both kevlar and carbon fiber this fabric combines the properties of the two fibers in each layer to deliver high strength to weight ratio high conformability impact resistance abrasion resistance dimensional stability and fatigue resistance.

Para aramid fibers such as kevlar and twaron which are slightly different have outstanding strength to weight properties and have high tenacity which makes it difficult to cut or fray. Carbon fiber is much easier to tool than kevlar so it can be used in complex canoe s hulls which require a. The important thing to take away is that carbon fiber is about twice as stiff as kevlar and about 5 times stiffer than glass. Typically it is spun into ropes or fabric sheets that can be used as such or as an ingredient in composite material.

Carbon fiber is by far the stiffer of the composite materials. Kevlar aramid is used for high performance composite applications where lightweight high strength and stiffness damage resistance and resistance to fatigue and stress rupture are important. The stiffness of carbon fiber kevlar and glass are very different. 130 179 gpa compared to carbon fiber 300 gpa and glass 81 gpa low elongation to break does not stretch much.

Carbon fiber is heat resistant and not susceptible to rust. Kevlar is a heat resistant and strong synthetic fiber related to other aramids such as nomex and technora developed by stephanie kwolek at dupont in 1965 this high strength material was used first commercially in the early 1970s as a replacement for steel in racing tires. Although graphite and carbon fiber canoes can be made to be as tough as steel they are mostly designed to limit weight and add stiffness. Kevlar boats are less expensive than carbon fiber boats because the material costs less.

/0.125CF-Kevlar-sml.jpg)